test

2 End hunger, achieve food security and improved nutrition and promote sustainable agriculture

goal 3

goal 4

goal 5

goal 6

goal 7

goal 8

goal 9

goal 10

goal 11

goal 12

goal 13

goal 14

goal 15

Goal 16

16.3: Promote the rules of law and the national and international levels and ensure equal access to justice for all.

16.5: Substantially reduce corruption and bribery in all their forms

16.7 Ensure responsive, inclusive, participatory and representative decision-making at all levels

16.b: Promote and enforce non-discriminatory laws and policies for sustainable development

Goal 17

Occupational Health and Safety

As indicated by the incorporation of occupational health and safety into the corporate value, Happy Workplace, BJC constantly emphasizes all employees' health and safety. The priority is also represented in BJC's 2024 materiality matrix, where BJC and stakeholders have prioritized workplace health and safety as a priority. The company is dedicated to preventing occupational injuries, illnesses, and deaths, as well as the resulting suffering and financial burden for employees and their families. Furthermore, BJC is dedicated to promoting the physical, mental, and emotional well-being of all individuals in order to ensure the company's long-term sustainability.

BJC has intention to operate business without the occurrence of accidents by setting target “Zero Accident” to persuade employees realize to the importance and work carefully, without accidents which cause of injuries from the working in every activity of operations.

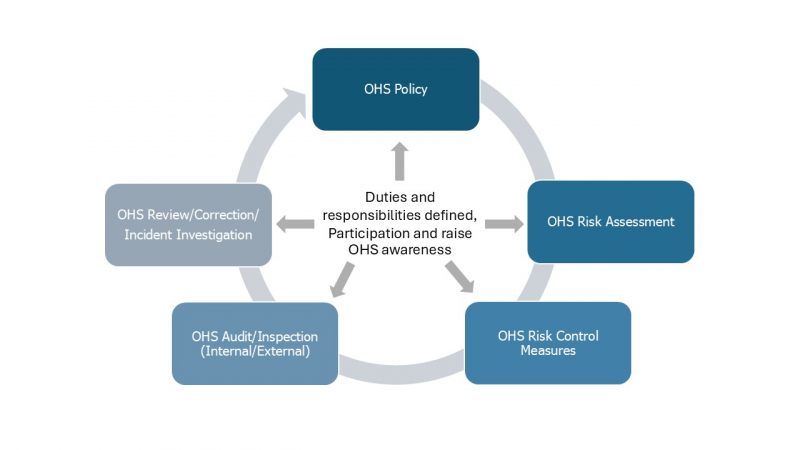

OHS Management Approach & Systemic Occupational Health and Safety Management Systems

BJC has various projects and measures to support the health and well-being of employees, including providing knowledge, raising awareness about health and safety, implementing practices, as well as measuring and evaluating results. Morover, Compliance with all relevant occupational health and safety laws, regulations, and standards, including OHSAS 18001:2007 and ISO45001:2018, is of BJC’s utmost importance. To further the company’s commitment to, the company established the BJC Worker Health and Safety Committee to provide employees and contractors with a voice in our monthly management meetings. Beyond that, BJC also implemented a Systemic Occupational Health and Safety Management System (OHSMS) and a comprehensive Safety, Occupational Health and Working Environment Policy that applies to all BJC and subsidiary operations. The goal of these systems and policies is to optimize safety at every stage of our operations, reducing the risk of accidents and hazards to the lowest possible level and ensuring the well-being of all employees, visitors, and individuals who work at BJC.

Safety, Occupational Health and Working Environment Policy

As stated in the Safety Policy, BJC actively strives to reduce the number of illnesses, injuries, and fatalities related to work, with the goal of achieving a zero-accident rate. This commitment is realized by closely monitoring and adhering to applicable laws, regulations, and standards, ensuring that BJC does not violate legal OHS requirements. In accordance to the policy, BJC is committed to the following actions;

- regular conducting occupational health and safety risk assessments to identify hazardous working environments that may result in injuries and fatalities,

- raising awareness of occupational health and safety among employees, suppliers, and contractors through training sessions to foster safety culture, and

- monitoring OHS performance at each site through the establishment of formal safety committees, and implement customized OHS initiatives throughout each supply chain.

BJC focuses on and supports maximum safety at all stages of operation to reduce the rate of accidents and hazards to minimum or zero, which employees may encounter while working. Therefore, the company has set important guidelines and standards that will facilitate continuous improvement and create a culture of occupational health and safety within the organization, which is an essential factor to lead the organization to achieve zero accident.

To ensure the maximum safety of every process of working, BJC has set a policy on safety, occupational health and working environment which covers development of safety management system and occupational health and working environment in accordance with laws, international standards and other relevant requirements. BJC regularly monitors and evaluates work performance according to safety, occupational health and working environment policy, in order to achieve the highest level of efficiency. Moreover, BJC encourages employees to recognize the importance of occupational health and safety through training and practice to ensure that all employees understand and comply with the policy. At BJC, the Occupational Health and Safety (OHS) training course for new employees is a comprehensive program designed to ensure a safe and productive work environment. This course covers essential safety protocols, hazard identification, and emergency response procedures tailored to the specific needs of the company's diverse operations. New employees learn about the company's safety culture, legal obligations, and the importance of proactive risk management. Through interactive sessions, practical demonstrations, and assessments, the training equips employees with the knowledge and skills necessary to maintain high safety standards and prevent workplace accidents, thereby fostering a secure and healthy workplace.

The Occupational Health and Safety Management System (OHSMS) has a process as follows,

- Policies and Management Approach

- Communicate and Controls

- Risk Assessment & Management (Quarterly)

- Audit by Central (Internal) and External Party (External and Internal Inspection)

- Incident Investigation Process

- Report Process Monthly to Management

OHS Governance & Continuous Improvement

BJC is committed to the continuous improvement of its Occupational Health & Safety (OHS) management system, ensuring that workplace safety remains a top priority across all operations. The company regularly evaluates and enhances its OHS policies, procedures, and performance metrics to align with ISO 45001:2018 standards, legal regulations, and global best practices.

The Board of Directors serves as the highest decision-making body endorsing the implementation of the OHS policy, reinforcing BJC’s corporate-wide commitment to workplace safety, employee well-being, and risk mitigation. This endorsement ensures that OHS principles are integrated into business operations, investment decisions, and strategic planning.

BJC Worker Health and Safety Committee

The BJC Worker Health and Safety Committee takes its role in ensuring proper implementation of OHS compliance seriously, closely overseeing adherence at each business unit. Beyond just compliance, the Committee serves as a representative of the employees and contractors, providing a voice for their concerns in monthly management and Safety, Health, and Environment (SHE) meetings. This gives employees and contractors a direct channel to express their views and ensures their well-being remains a top priority at BJC.

Going beyond its compliance responsibilities, the BJC Worker Health and Safety Committee actively engages with employees and contractors to gather insights on OHS issues. The Committee incorporates employee engagement results into its efforts to identify and evaluate hazardous environments, investigate incidents, conduct audits and inspections, and provide training to enhance the OHSMS. In accordance with ISO 45001 and ISO 14001 standards, annual management reviews of the OHSMS are conducted to ensure that BJC continuously creates a safe and healthy workplace for all employees and contractors. By prioritizing employee and contractor well-being, BJC is committed to making the workplace a place where everyone can thrive.

Occupational Health and Safety Risk Identification Assessment and Management

Guided by the established Systemic Occupational Health and Safety Management System (OHSMS), all occupational health and safety related risks and hazardous environment in all BJC operations are regularly assessed to minimize all types of risks and injuries. This assessment focuses on production process at manufacturing based operations, and all Big C stores, where there are large and heavy machineries, presenting high injury risk levels for employees and contractors.

BJC conducts OHS assessment at least semi-annually, in accordance with ISO standards, aiming to actively identify operations with significant negative OHS risks. In addition, assessments are conducted for all service providers and external contractors to assess the efficiency and effectiveness of OHS management and frequency of OHS incident in normal, abnormal and emergency conditions, in order to rank risks levels accordingly.

BJC has continuously developed and implemented various controls and mitigation measures to manage relevant OHS risk and lower risk impacts on employees, contractors, and BJC's operations. Controls that have been implemented include updating operational controls to account for OHS risks, improving engineering designs to reduce risks, and integrating ambitious OHS objectives or targets into operations. In order to evaluate the continuous improvement of the OHSMS, the performance of implemented changes is monitored by on-site OHS personnel and reviewed by the responsible department head.

BJC conducts comprehensive workplace health and safety risk assessments to ensure safe working conditions for employees, contractors, and suppliers. This includes regular hygiene audits, operational risk evaluations, and safety assessments in high-risk areas such as construction, logistics, and hazardous material handling. All on-site contractors and vendors must comply with BJC’s OHS policies to maintain workplace safety standards.

Risk Assessment for Health & Safety in New Operations and Projects

BJC integrates comprehensive health and safety risk assessments as a core component of its due diligence process for all new operations and projects. Before initiating any new business activities, expansions, or facility developments, the company conducts proactive risk evaluations to identify, assess, and mitigate potential health and safety hazards.

Key measures include:

- Pre-operational risk assessments to evaluate potential workplace hazards before project approval.

- Safety compliance checks to ensure alignment with ISO 45001:2018, national safety regulations, and industry best practices.

- Environmental and occupational health impact assessments to mitigate risks related to air quality, noise exposure, hazardous materials, and emergency preparedness.

- Stakeholder engagement involving employees, contractors, and external safety experts to identify site-specific safety concerns.

Risk Assessment and Prioritization

The 2024 assessment highlighted the Health and Safety of Employees as a critical human rights risk within BJC's manufacturing operations. The nature of BJC’s business inherently involves health and safety risks, particularly in factories where employees are exposed to extreme heat and constant noise from machinery and equipment. These conditions can lead to severe health issues, including heat-related illnesses and hearing loss. Given the significant risks identified, BJC prioritizes these hazards based on their potential impact and the frequency of occurrence. By leveraging LTIFR data, BJC can focus on areas with higher injury rates, ensuring that the most pressing issues receive immediate attention. This targeted approach facilitates the effective allocation of resources and the implementation of tailored action plans.

Proactive Identification and Control of Work-Related Hazards

BJC follows a structured approach to identifying, assessing, and controlling workplace hazards using the Hierarchy of Controls to eliminate or minimize risks before incidents occur. The company applies this process both routinely and for non-routine tasks, ensuring continuous risk mitigation across all operations.

1. Hazard Identification and Risk Assessment

BJC systematically identifies and evaluates work-related hazards through:

- Routine assessments: Conducted through daily safety checks, scheduled workplace inspections, and employee hazard reporting systems.

- Non-routine assessments: Conducted before new processes, equipment installations, or hazardous work activities to proactively mitigate potential risks.

- Job Safety Analysis (JSA): Used to assess risks associated with high-risk tasks and ensure appropriate preventive measures are in place

- Real-time digital reporting systems: Enable workers to log potential hazards immediately, ensuring prompt response and mitigation.

2. Applying the Hierarchy of Controls

BJC integrates the ISO 45001:2018-aligned Hierarchy of Controls to proactively eliminate and control workplace hazards before they pose a threat:

- Elimination:

- Removing hazardous materials from operations when possible.

- Automating processes to reduce manual handling of hazardous substances.

- Substitution:

- Replacing high-risk equipment, chemicals, or procedures with safer alternatives.

- Switching to ergonomic tools to reduce strain-related injuries.

- Engineering Controls:

- Installing machine guards, ventilation systems, and noise-reducing barriers to physically separate employees from hazards

- Implementing automated safety shutdowns in high-risk areas.

- Administrative Controls:

- Implementing strict standard operating procedures (SOPs), rotating shifts, and employee fatigue management programs to reduce human error risks.

- Conducting mandatory safety training, hazard awareness workshops, and emergency response drills for all employees and contractors.

- Personal Protective Equipment (PPE) (last resort):

- Providing certified PPE for tasks involving chemical exposure, airborne particles, or physical hazards.

- Regular PPE maintenance and fit testing to ensure optimal protection.

By prioritizing hazard elimination and implementing multiple layers of control, BJC minimizes workplace risks and fosters a proactive safety culture.

|

Internal Safety Inspection |

Internal Safety Inspection |

Prioritization and Integration of Action Plans with Quantified Targets at BJC

Lost-Time Injury Frequency Rate (LTIFR) as a Quantified Target: To effectively address Occupational Health and Safety (OHS) risks, BJC and its subsidiaries utilize the Lost-Time Injury Frequency Rate (LTIFR) as a key performance indicator. This metric quantifies the frequency of injuries resulting in lost work time per million hours worked. By employing LTIFR as a benchmark, BJC can objectively measure safety performance, identify trends, and set specific, data-driven targets for improvement. These quantified targets play a crucial role in risk assessment and prioritization, enabling the company to systematically address the most significant hazards within their operations.

Integration of Action Plans

BJC’s integration of action plans to address identified OHS risks involves a multifaceted strategy. The company has implemented several proactive measures to mitigate health and safety risks, particularly those related to heat and noise exposure in manufacturing operations:

- Regular Safety Training: Continuous safety training sessions are held to ensure that all employees are well-versed in the latest safety protocols and best practices. These sessions are crucial in equipping workers with the knowledge and skills necessary to navigate potential hazards effectively.

- Provision of Protection Devices: To combat heat and noise exposure, BJC provides heat protection gear and hearing protection devices to employees. These protective measures are essential in preventing heat-related illnesses and hearing damage, thereby safeguarding employees’ health and well-being.

- Regular Health Checks: Routine health assessments, including hearing tests, are conducted to monitor and maintain employees' health. These checks enable early detection and management of any adverse effects caused by the work environment, ensuring timely intervention.

- Effective Communication: Health and safety information is continuously updated and disseminated through strategically placed notice boards across the facilities. This ensures that employees are always informed about the latest safety measures, potential hazards, and any changes in safety protocols.

- Whistleblowing System: BJC has implemented a whistleblowing system that allows employees to report safety concerns or violations anonymously. This system fosters a culture of accountability and vigilance, encouraging workers to actively participate in maintaining a safe and healthy workplace.

Work-Related Ill Health

BJC maintains a proactive approach to preventing work-related ill health through its Occupational Health & Safety (OHS) management system, aligned with ISO 45001:2018. In 2024, there were no reported fatalities or recordable cases of work-related ill health among employees or non-employee workers under BJC’s operational control.

Key work-related health risks identified include ergonomic strain, respiratory exposure, and occupational stress. These hazards are assessed through workplace health screenings, employee health monitoring programs, and risk evaluations. While no reported cases occurred during the reporting period, BJC continues to implement preventive measures using the Hierarchy of Controls, including ergonomic workstation improvements, ventilation upgrades, mental health support programs, and enhanced PPE requirements for high-risk roles.

Integration of Actions to Prepare for and Respond to Emergency Situations

1. Regular Training and Drills

1.1 Emergency Training

BJC places a high priority on the safety and preparedness of its employees, recognizing that regular training is essential for effective emergency response. To this end, the organization conducts comprehensive training sessions and crisis drills that cover a wide range of potential emergency scenarios.

- Fire Drills: These are conducted regularly to ensure that all employees are familiar with evacuation routes, the location of fire extinguishers, and the correct procedures to follow in the event of a fire. Employees learn how to identify fire hazards, use firefighting equipment, and safely evacuate the premises.

- Active Shooter Drills: Given the increasing incidence of workplace violence, BJC conducts active shooter drills to train employees on how to react swiftly and effectively in such situations. These drills focus on the "Run, Hide, Fight" strategy, helping employees to make quick decisions to protect themselves and others.

- Evacuation Drills: These drills are designed to prepare employees for various emergency scenarios that may require rapid evacuation. Employees practice orderly and efficient evacuation procedures, ensuring that everyone knows their roles and responsibilities, as well as the location of safe assembly points.

Each training session includes detailed instructions, role-playing exercises, and debriefing sessions to reinforce learning and address any questions or concerns employees may have.

1.2 Continuous Improvement

BJC understands that emergency preparedness is not a one-time effort but an ongoing process of learning and improvement. To facilitate this, the organization implements a continuous improvement strategy through monthly case studies and incident reviews.

- Monthly Case Studies: These sessions analyze real-life incidents, both internal and external, to extract valuable lessons. By examining what went well and what could have been improved in each case, employees gain insights that can be applied to future emergency situations. These case studies cover a range of scenarios, from natural disasters to man-made crises, ensuring a comprehensive understanding of various threats.

- Incident Reviews: After any emergency drill or actual incident, BJC conducts thorough reviews to assess the effectiveness of the response. These reviews involve detailed analysis of the actions taken, the communication protocols followed, and the overall outcome. Feedback from these reviews is used to identify strengths and weaknesses in current emergency plans.

- Recommendations for Refinement: Based on the findings from case studies and incident reviews, BJC develops specific recommendations for enhancing emergency response plans. This could include updates to evacuation routes, changes in communication strategies, or additional training requirements. These recommendations are implemented promptly to ensure that the organization remains at the forefront of emergency preparedness.

By integrating regular training and drills with a robust continuous improvement process, BJC ensures that its employees are well-prepared for any emergency situation. This proactive approach not only enhances safety but also fosters a culture of vigilance and readiness throughout the organization

2. Centralized Incident Reporting and Communication

- Incident Identification: The Loss and Prevention (LP) department uses a centralized system to identify and report incidents, including fire, floods, and crisis drills (e.g., active shooter scenarios).

- Monthly Reports: Consolidated incident reports are communicated to the Store’s Safety Committee and posted on poster boards for employee awareness. The Crisis Management Support Team (CMST) disseminates these reports to Big C stores via email and the CMST line group, ensuring wide communication.

3. Integration with Business Continuity Plans

- Alignment with BCM: Emergency response actions are aligned with Business Continuity Plans to maintain operations during disruptions.

- Resource Allocation: Resources such as emergency supplies, communication tools, and protective equipment are allocated as part of BCM plans.

4. Fostering a Culture of Safety

- Safety Boards and Communication: Regular updates on safety measures and protocols are communicated through safety information boards and emails.

- Whistleblowing System: An anonymous reporting system allows employees to report safety concerns, promoting vigilance and proactive risk identification.

Integrating emergency preparedness with BJC’s Business Continuity Management ensures comprehensive emergency handling and operational resilience. Regular training, continuous communication, and a culture of safety are key elements supporting this approach.

Active shooter drills, Photo Credit: Chiang Mai News

Occupational Health and Safety Training

To effectively reduce OHS incidents, BJC believes that all employees must actively participate in identifying and reporting potential OHS risk environments and incidents to supervisors. To accomplish this, all employees must be equipped with the knowledge and skills required to effectively identify potential OHS hazards in the workplace. BJC has included OHS training as part of the mandatory training that all employees must complete as part of the orientation process. This is to raise OHS awareness and highlight BJC's commitment to employee occupational health and safety. Moreover, all employees are also given training in office ergonomics, basic first aid and CPR, and basic firefighting. Relevant topic professionals such as Advance Firefighters and the Emergency Response Team conduct training sessions for first aid and CPR, ensuring competent and accurate training material for employees. To protect the health and safety of contractors and visitors, all contractors receive OHS training, which ensures compliance with safety practices and lowers the risk of injuries throughout the value chain.

Incident Investigation Process

Employees are responsible for following the Incident Investigation Process if they identify or observe a work-related hazardous environment or situation. The same procedure applies if contractors identify or observe work-related hazardous environments or situations. The incident investigation process also covers work-related injuries, ill health and diseases.

1. Incident Response

Employees are responsible for reporting incidents to relevant supervisors, who are responsible for addressing each concern and following the investigation process to remediate the hazardous incident as soon as possible. It is emphasized that if any employee believes that an incident poses a high risk to the health and well-being of employees and their respective peers, all employees have the right to declare a stop work situation in order to remove themselves and their peers from the unsafe environment, and they are guaranteed to be protected from retaliation.

2. Record Data

All identified or observed work-related hazardous environment or circumstance must be accurately recorded by relevant supervisors into the centralized system.

3. Root Cause Investigation & Preventive Actions

Relevant supervisors are responsible for conducting a transparent incident investigation process to review the situation and identify the root cause of such event so that it can be managed appropriately and avoided in the future.

4. Report

To finish, if a hazardous event occurs in an operation that poses an obvious OHS risk, BJC will disclose the incident to all subsidiaries for investigation, in order to reduce the possibility of a similar incident occurring in other subsidiaries.

Work-Related Hazards and Ill Health Initiatives

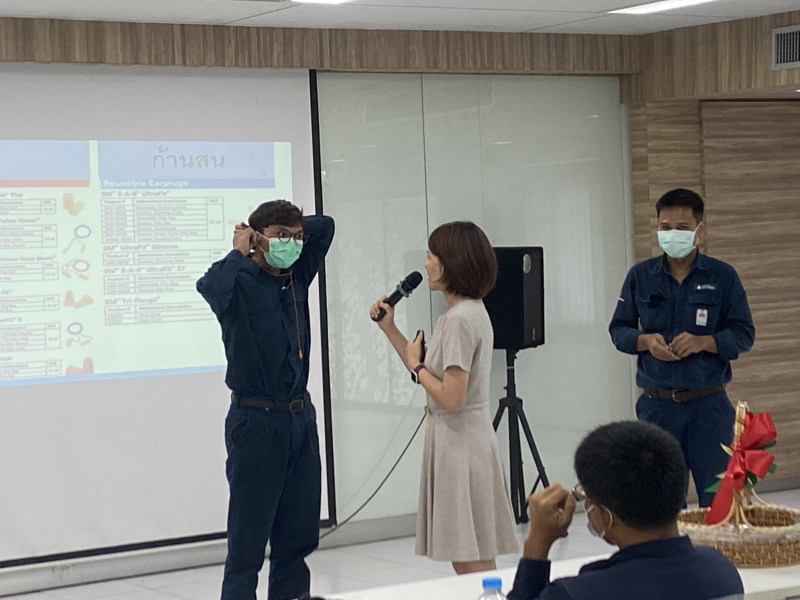

Hearing Conservation Program (HCP)

To reduce and prevent health risks in the packaging business, one of the Occupational Health and Safety (OHS) initiatives implemented by BJC is the Hearing Conservation Program (HCP), particularly for high-risk groups such as employees at TGI and TMG, where the risk of hearing loss is significant.

BJC has been implementing this program continuously, beginning with workplace noise risk assessments. Measures include monitoring noise levels, reducing exposure, and preventing hearing loss through various strategies such as:

- Reducing noise at the source

- Rotating workers or limiting their exposure time in noisy areas

- Providing appropriate hearing protection, such as earplugs or earmuffs

- Training employees on the hazards of noise exposure and the importance of hearing conservation

- Conducting audiometric testing

- Regularly reviewing the effectiveness of the program

In 2024, noise level measurements were conducted in operational areas, and audiometric testing was performed for employees in high-risk groups as part of a proactive monitoring initiative. Additionally, occupational health specialists from Saraburi Hospital conducted awareness training sessions for four groups of employees, with a total of 160 participants.

Hearing Program Training Hearing Program Training

Material Handling Equipment (MHE) Training

The distribution centers of the retail business have implemented Material Handling Equipment (MHE) training for relevant employees. As MHE operations are a core activity within the distribution centers, it is essential that employees understand and follow correct and safe usage procedures to reduce the risk of accidents caused by improper handling.

Safety inspections

Regular safety inspections are conducted monthly by the Safety Committee, focusing on both unsafe conditions and unsafe acts. These inspections ensure that the risk reduction and control measures established are effectively implemented, helping to minimize the occurrence of workplace accidents.

Training : Pandemic Preparedness and Response : HIV / AIDS

BJC is steadfast in its dedication to safeguarding the health and enhancing the quality of life of all our employees. BJC actively support sustainable health initiatives at both societal and global levels.

As part of the commitment to promoting a safe and equitable workplace, BJC has implemented comprehensive training programs aimed at increasing awareness and understanding of HIV/AIDS. These programs are designed to:

• Provide accurate information about HIV/AIDS.

• Educate employees on the "U=U" (Undetectable = Untransmittable) concept to reshape perceptions of individuals living with HIV.

• Emphasize the importance of creating a safe, fair, and non-discriminatory workplace in line with international standards.

• Foster an organizational culture that values understanding and equality.

Through these efforts, BJC reaffirms its unwavering commitment to the health, well-being, and equal treatment of all employees, fostering a workplace environment that is both inclusive and supportive.

Training Course : Pandemic Preparedness and Response : HIV / AIDS

OHS Criteria in Procurement and Contractual Requirements

BJC has embedded ESG criteria as a fundamental element in supplier selection and evaluation processes, with OHS being a key part of these ESG criteria. In addition, BJC has established a Supplier Code of Conduct to serve as a framework for business practices for all suppliers within the Group. OHS is one of the requirements that suppliers must comply with, which includes providing a working environment that meets the Occupational Health and Safety Act, applicable laws, and relevant regulations. Suppliers must also provide employees with adequate and appropriate personal protective equipment, aligned with workplace risks, ensure its readiness for use, and enforce its proper usage. This reflects BJC’s commitment to managing and developing its business sustainably, while maintaining social responsibility and reducing business risks.

Moreover, as stated in BJC's Supplier Code of Conduct, suppliers shall attend and offer training on safety, occupational health, and working environment to employees and other relevant stakeholders to raise awareness and reduce operational health and safety incidents.

|

OHS Safety Training for Suppliers |

OHS Safety Training for Suppliers |

2024 Performance

Fatalities

|

Fatalities |

2021 |

2022 |

2023 |

2024 |

Target for 2024 |

| Employee |

0 |

0 |

0 |

0 |

0 |

| Contractor |

0 |

0 |

0 |

0 |

0 |

LTIFR - Employee

|

LTIFR - Employee |

Unit |

2021 |

2022 |

2023 |

2024 |

Target for 2024 |

| Employees |

n/millions of hours worked |

1.98 |

1.79 |

2.12 |

2.07 | 2.10 |

| Data Coverage |

% of revenues |

89.98 |

91.37 |

91.42 |

91.81 |

LTIFR - Contractor

|

LTIFR - Contractor |

Unit |

2021 |

2022 |

2023 |

2024 |

Target for 2024 |

| Contractor |

n/millions of hours worked |

0.57 |

0.51 |

0.50 |

0.75 | 0.50 |

| Data Coverage |

% of revenues |

89.98 |

91.37 |

91.42 |

91.81 |

Remark: LTIFR - Contractor does not include working hours of the contractors that promote sales of product or service such as product consultants.

In 2024, the LTIFR increased to 0.75, the rise in LTIFR in 2024 highlights the importance of continuous improvement in safety practices. Upon investigation, it was found that approximately 95% of the incidents were caused by failure to follow safe work procedures. To prevent recurrence, the company conducted refresher training, shared incidents through Safety Alerts to raise awareness, and improved the related work environment and equipment to enhance safety. These measures aim to strengthen the safety culture and reduce the likelihood of similar incidents occurring in the future.

Working Hours

- Employee : 86,710,095 hours

- Contractor : 35,853,715 hours

Workers Covered by OHS Management System 2024

| Category | Number | Percentage from Total Employees / Total Contractors (%) |

| Employees covered by OHS management system |

34,689 |

100 |

| Workers (non-employees i.e. contractors) covered by OHS management system |

22,694 |

100 |

|

Employees covered by internally audited OHS system |

34,689 |

100 |

| Workers (non-employees i.e. contractors) covered by internally audited OHS system |

22,694 |

100 |

|

Employees covered by externally audited/certified OHS system * |

2,286 * |

100 * |

|

Workers (non-employees i.e. contractors) covered by externally audited/certified OHS system * |

22,694 * | 100 * |

* BJC’s OHS management system with third-party certification (e.g., ISO 45001) currently applies to business units where the nature of operations involves higher occupational health and safety risks — notably in manufacturing activities related to consumer products, packaging, and food. These include factories of Rubia Industries, BJC Cellox, BJC Glass (conducted major maintencance in 2024), Thai Beverage Can, and BJC Foods. External certification is prioritized for these units due to regulatory requirements, industry standards, and risk management considerations.

Occupational Health and Safety Services

Beyond merely complying with relevant laws and regulations, BJC has taken a proactive approach to promoting employee health and well-being. Regular assessments of hazardous and occupational health and safety are conducted across all operations, and flexible working environments, childcare facilities and maternity and paternity leave initiatives are all in place to support employees.

Moreover, BJC has implemented comprehensive workplace health and safety measures during epidemic or pandemic situations to protect employees. These include remote work policies, workplace sanitation improvements, personal protective equipment (PPE) provisions, vaccination support programs, and regular health screenings to ensure a safe and healthy working environment.

Fitness Center and Exercise Classes

All employees could access the fitness center during 06:00 – 22:00 hours on week day. Beyond that, the company also initiated special corporate rates for its employees who would like to apply for a membership at Jetts Fitness center nationwide. Moreover, every Wednesday after working hours, an exercise class was available for the employees to join. The class took place at the new auditorium and it comprised of cardio exercise such as body combat and Zumba dance.

Standard Certification

In 2024, BJC Big C and its subsidiaries attained the following International Organization for Standardization (ISO) standards:

| ISO 45001:2018 | ISO 14001:2015 | ISO 9001:2015 |

- ISO 45001:2018 - Occupational Health and Safety Management Systems

- ISO 14001:2015 - Environmental Management Systems

- ISO 9001:2015 - Quality management system (QMS)

| Consumer | Personal care | Packaging | Engineering | Modern Retail | |

|

|

|

|

|

||

|

|

|

||||

|

|

|||||

|

|

| ISO 45001:2018 - Occupational Health and Safety Management Systems Total 9 Site | |||||||

|

Consumer -Thailand 2 Site |

Personal care - Thailand 1 Site |

Packaging - Thailand 5 Site |

Engineering - Thailand 1 Site |

||||

| Berli Jucker Cellox (CPC) | Rubia Industries (RIL) | Thai Glass Industries (TGI) | Thai Scandic Steel (TSS) | ||||

| Berli Jucker Foods (BJF) | Thai Malaya Glass (TMG 1) | ||||||

| Thai Malaya Glass (TMG 2) | |||||||

| Thai Beverage Can (TBC 1) | |||||||

| Thai Beverage Can (TBC 2) | |||||||

BJC has obtained ISO 45001:2018 certification, which requires independent external verification by accredited certification bodies. External audits are conducted annually by SGS (Thailand) Ltd., BSI Group (Thailand) Co., Ltd., LRQA, and Bureau Veritas, depending on the operation. These audits cover occupational health and safety management systems across our key operations. The certification ensures a structured and proactive approach to managing health and safety risks, reflecting our strong commitment to employee well-being.

|

|

|

|

|

|

| ISO 14001:2015 - Environmental Management Systems Total 9 Site | |||||||

|

Consumer -Thailand 2 Site |

Personal care - Thailand 1 Site |

Packaging - Thailand 5 Site |

Engineering - Thailand 1 Site |

||||

| Berli Jucker Cellox (CPC) | Rubia Industries (RIL) | Thai Glass Industries (TGI) | Thai Scandic Steel (TSS) | ||||

| Berli Jucker Foods (BJF) | Thai Malaya Glass (TMG 1) | ||||||

| Thai Malaya Glass (TMG 2) | |||||||

| Thai Beverage Can (TBC 1) | |||||||

| Thai Beverage Can (TBC 2) | |||||||

| ISO 9001:2015 - Quality management system (QMS) Total 9 Site | |||||||

|

Consumer -Thailand 2 Site |

Personal care - Thailand 1 Site |

Packaging - Thailand 5 Site |

Engineering - Thailand 1 Site |

||||

| Berli Jucker Cellox (CPC) | Rubia Industries (RIL) | Thai Glass Industries (TGI) | Thai Scandic Steel (TSS) | ||||

| Berli Jucker Foods (BJF) | Thai Malaya Glass (TMG 1) | ||||||

| Thai Malaya Glass (TMG 2) | |||||||

| Thai Beverage Can (TBC 1) | |||||||

| Thai Beverage Can (TBC 2) | |||||||

OHS Awards and Recognitions

Berli Jucker Cellox (CPC)

- Honored by the Ministry of Labour for its Excellent practices’ establishment on occupational safety and health at the national level in 2023, achieving the silver level as the 7th year of achievement.

- Achieved the silver level in the Healthy, Safety, and Happy Workplace Project 2023, as awarded by the Ministry of Public Health.

Berli Jucker Public Company Limited

- Honored with the Thailand Labor Management Excellence Award 2023 by the Department of Labor Protection and Welfare, Ministry of Labor.

- Acknowledged for its commitment to safety through the Zero Accident Campaign 2023, as awarded by the Ministry of Labour.

Thai Glass Industries (TGI)

- TGI was recognized by the Ministry of Labour for its Excellent practices’ establishment on occupational safety and health at the national level in 2023, marking the company’s fifth year of achievement in this area.

Thai Malaya Glass (TMG)

- TMG was commended by the Ministry of Labour for its Excellent practices’ establishment on occupational safety and health at the national level in 2023, marking the company’s third year of achievement in this domain.

- TMG received accolades from the Ministry of Labour for its Excellent practices’ establishment on labor relations and welfare at the national level in 2023, marking the company’s eighth year of achievement in this area.

- TMG was recognized by the Ministry of Labour for its Excellent practices’ establishment on occupational safety and health at the national level in 2023, marking the company’s fourth year of achievement in this area.

Rubia Industries (RIL)

- RIL received accolades from the Ministry of Labour for its Excellent practices’ establishment on labor relations and welfare at the national level in 2023, commemorating the company’s fourth consecutive year of excellence.

Thai Scandic Steel (TSS)

- TSS has been awarded the Green Industry Level 3 (Green System) certification by the Ministry of Industry in 2023.